Sodiceram: The Modern Revolution Redefining Pottery Art

Pottery has always been more than just clay and fire—it’s a reflection of culture, creativity, and craftsmanship. For centuries, artisans have shaped earth into art using methods passed down through generations. But what happens when tradition meets innovation? That’s where Sodiceram steps in. This groundbreaking technique is transforming pottery into a fusion of science and art, opening new doors for creators worldwide. Curious about how it works and why artists can’t stop talking about it? Let’s dive in.

From Clay to Code: How Pottery Is Evolving

For thousands of years, pottery has relied on the human touch—wheel throwing, hand sculpting, and kiln firing. Every piece carried its imperfections proudly, showcasing the artist’s soul. But as modern needs evolve, potters are searching for ways to blend precision with passion. Enter Sodiceram, a method that merges age-old pottery traditions smart pottery tools with cutting-edge materials and digital precision. Unlike conventional pottery that depends on natural clay alone, technology in ceramic art enhances it with engineered compounds, resulting in stronger, more resilient creations. Think of it as pottery 2.0—classic craftsmanship upgraded for the modern era.

The Science That Makes Sodiceram Special

At its heart, Sodiceram is both an art form and a scientific breakthrough. The secret lies in its innovative clay composition, which integrates minerals designed to improve heat resistance and durability. When fired, the material bonds at a molecular level, drastically reducing cracks and flaws. Even the firing process itself is smarter—temperature sensors ensure even heat distribution, giving every piece the perfect finish. And that’s not all. The glazes used in green ceramic solutions are eco-friendly, producing rich, vibrant colors without the harmful chemicals found in traditional ceramic coatings. It’s beauty and sustainability rolled into one sleek process.

Why Artists Are Falling in Love with Sodiceram

So, what makes this technique a favorite among modern potters? For one, it saves time. Sodiceram shortens firing cycles without compromising quality, meaning artists can produce more pieces with less energy. The results? Faster turnaround and lower costs. The material’s flexibility also encourages experimentation—creators can explore complex shapes, textures, and finishes once thought impossible. Beyond efficiency, there’s a deeper appeal: consistency without losing character. Every sustainable clay modeling piece retains the soul of handmade pottery, yet benefits from the reliability of technology. It’s like giving artists a superpower—control and creativity combined.

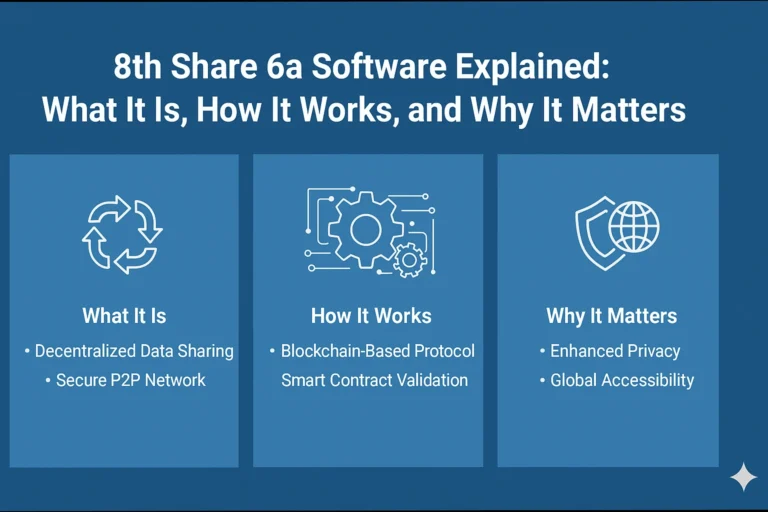

Sustainability at the Core of Sodiceram

Traditional pottery, while beautiful, often comes at an environmental cost. High-energy kilns, toxic glazes, and waste materials all add up. next-generation ceramics was designed to change that narrative. The process consumes less energy, minimizes waste, and uses earth-friendly compounds. By reducing emissions and reusing heat efficiently, it helps studios lower their carbon footprint. Many artistic clay creations practitioners also ceramic engineering process source their raw materials sustainably, ensuring every piece is as kind to the planet as it is to the eye. It’s not just about making art—it’s about making a difference.

Real Artists, Real Results

The rise of Sodiceram has already inspired incredible stories. Ceramicist Elena Cruz, for instance, found that the method allowed her to create lightweight yet durable sculptures that survived long outdoor exhibitions without cracks. Meanwhile, Kenji Tanaka, a designer known for minimalistic ceramics, credits smart pottery tools for enabling him to achieve flawless matte finishes impossible with regular glazes. Even large-scale pottery studios are adopting the technique to streamline production while maintaining an artisan touch. These stories prove one thing: ceramic engineering process isn’t just a fad—it’s the future.

What Lies Ahead for Sodiceram and Pottery

Looking ahead, Sodiceram is poised to become a cornerstone of sustainable pottery production. As researchers continue improving material science, we’ll likely see even more adaptable clays and energy-efficient processes. Digital tools like 3D modeling and smart kilns could soon integrate seamlessly with pottery innovation, letting artists visualize and craft intricate designs with unprecedented precision. The line between artisan and engineer is blurring—and that’s exactly what makes this new era of pottery so exciting.

Conclusion

Pottery has always been about transformation—turning humble clay into art that lasts centuries. With Sodiceram, that transformation now extends beyond aesthetics to sustainability, strength, and innovation. It honors the roots of traditional craftsmanship while boldly stepping into the future. Whether you’re an artist, collector, or simply someone who appreciates creativity, digital pottery design represents what’s next: pottery that’s not only beautiful but built to endure. In the evolving story of ceramics, advanced clay crafting isn’t just a new chapter—it’s a revolution.

FAQS

1. What is Sodiceram?

Sodiceram is an innovative pottery technique that blends traditional clay artistry with modern material science and technology for stronger, sustainable ceramics.

2. How is Sodiceram different from traditional pottery?

Unlike conventional pottery, sustainable ceramic production uses advanced materials and temperature control to improve durability, precision, and eco-friendliness.

3. Is Sodiceram environmentally friendly?

Yes! innovative pottery methods reduces energy consumption and waste by using eco-safe materials and efficient firing methods, making it a greener pottery alternative

4. Who can use Sodiceram techniques?

Both professional potters and beginners can use modern ceramic technology. Its flexibility allows artists to experiment with new shapes, colors, and finishes easily.

5. What are the benefits of Sodiceram pottery?

Sodiceram offers superior strength, vibrant color quality, reduced firing time, and sustainable production—all while preserving artistic authenticity.